Supply OEM/ODM Cold Room Building 50mm/75mm/100mm/150mm/200mm/300mm PU/PIR/PUR/Puf/Polyurethane/Structural Insulated Sandwich Panel for Cold Storage Insulation PU Panels

We insist on offering good quality generation with very good business enterprise concept, honest income as well as best and fast assistance. it will bring you not only the premium quality product or service and huge profit, but probably the most significant is usually to occupy the endless market for Supply OEM/ODM Cold Room Building 50mm/75mm/100mm/150mm/200mm/300mm PU/PIR/PUR/Puf/Polyurethane/Structural Insulated Sandwich Panel for Cold Storage Insulation PU Panels, President of our company, with whole staff members, welcomes all prospective buyers to go to our corporation and inspect. Let us cooperate hand in hand to create a fantastic long term.

We insist on offering good quality generation with very good business enterprise concept, honest income as well as best and fast assistance. it will bring you not only the premium quality product or service and huge profit, but probably the most significant is usually to occupy the endless market for Cold Room and PU Sandwich Panels, Our company will continue to serve customers with best quality, competitive price and timely delivery & the best payment term! We sincerely welcome friends from all over the world to visit& cooperate with us and enlarge our business. If you are interested in our merchandise, remember to do not hesitate to contact us, we’ll be happy to offer you with further information!

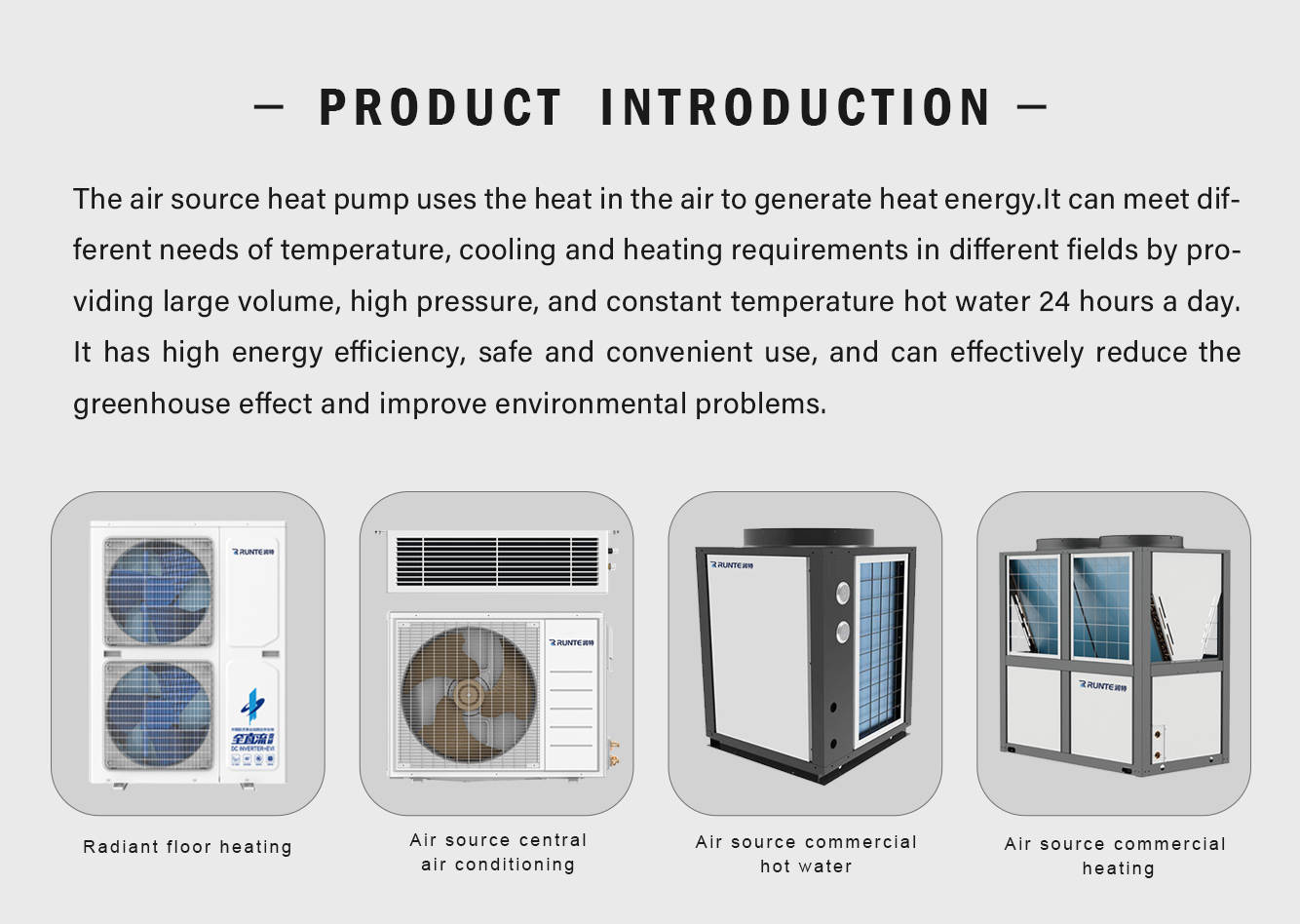

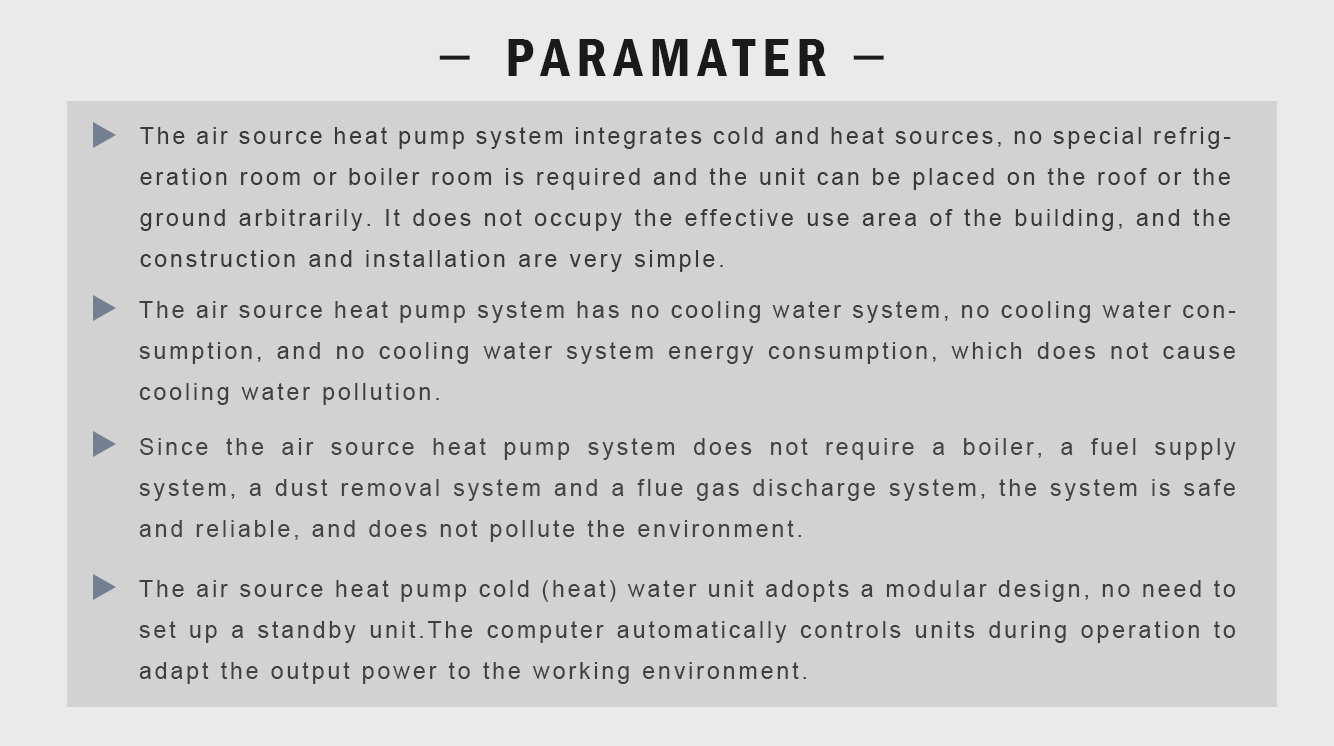

Parameter

| Unit Parameter Table | |||

| Air-cooled Module Unit Parameter Table | |||

| Unit Type Unit parameters |

ZGR-65ⅡAG2 | ZGR-130ⅡAG2 | |

| Rated Refrigeration (A35/W7℃) |

Cooling Capacity(kW) | 65 | 130 |

| Power(kW) | 20.3 | 40.6 | |

| EER | 3.20 | 3.20 | |

| Rated Heating (A7/W45℃) |

Heating Capacity(kW) | 70 | 140 |

| Power(kW) | 20.5 | 41.0 | |

| COP | 3.41 | 3.41 | |

| Mains | 380V/3N~/50Hz | ||

| Maximum Operating Current(A) | 58 | 115 | |

| Cooling Operating Ambient Temperature Range(℃) | 16~49 | ||

| Heating Operating Ambient Temperature Range(℃) | -15~28 | ||

| Cooling Water Temperature(℃) | 5~25 | ||

| Heating Water Temperature(℃) | 30~50 | ||

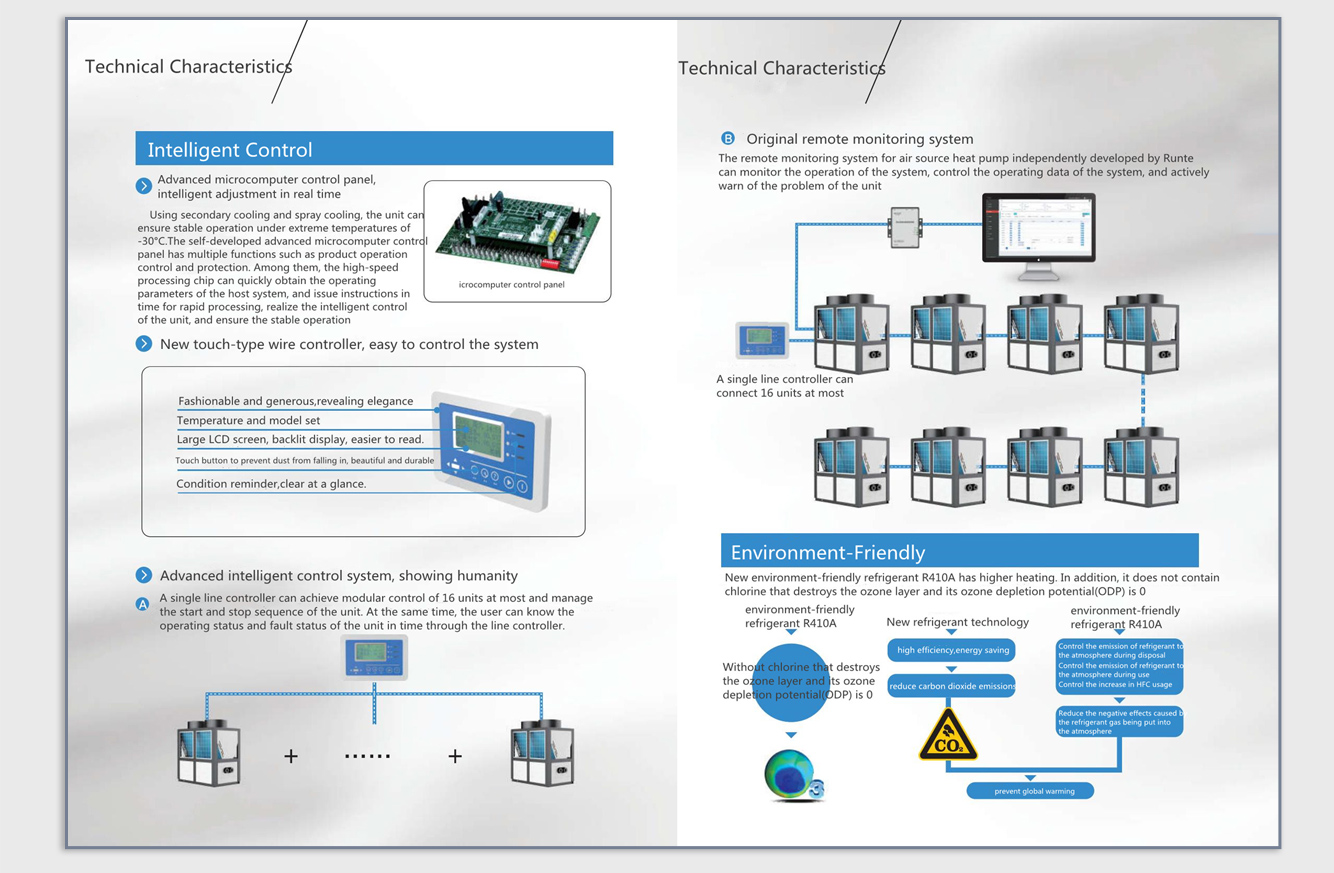

| Refrigerant | R410A | ||

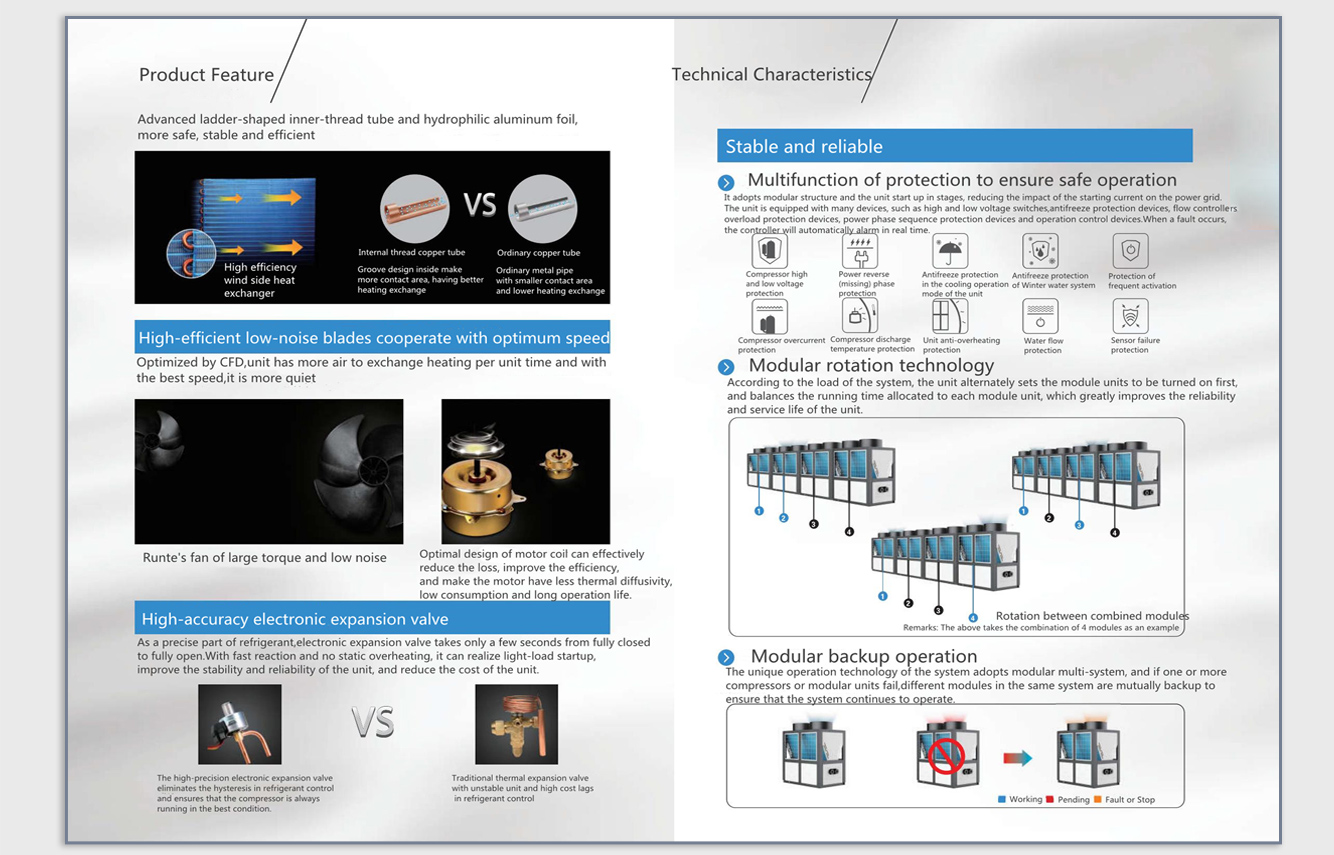

| Safeguard | Higher-lower voltage protection, antifreeze protection, overload, water flow protection, etc. | ||

| Capacity Adjustment Method | 0~100% | 0~50%~100% | |

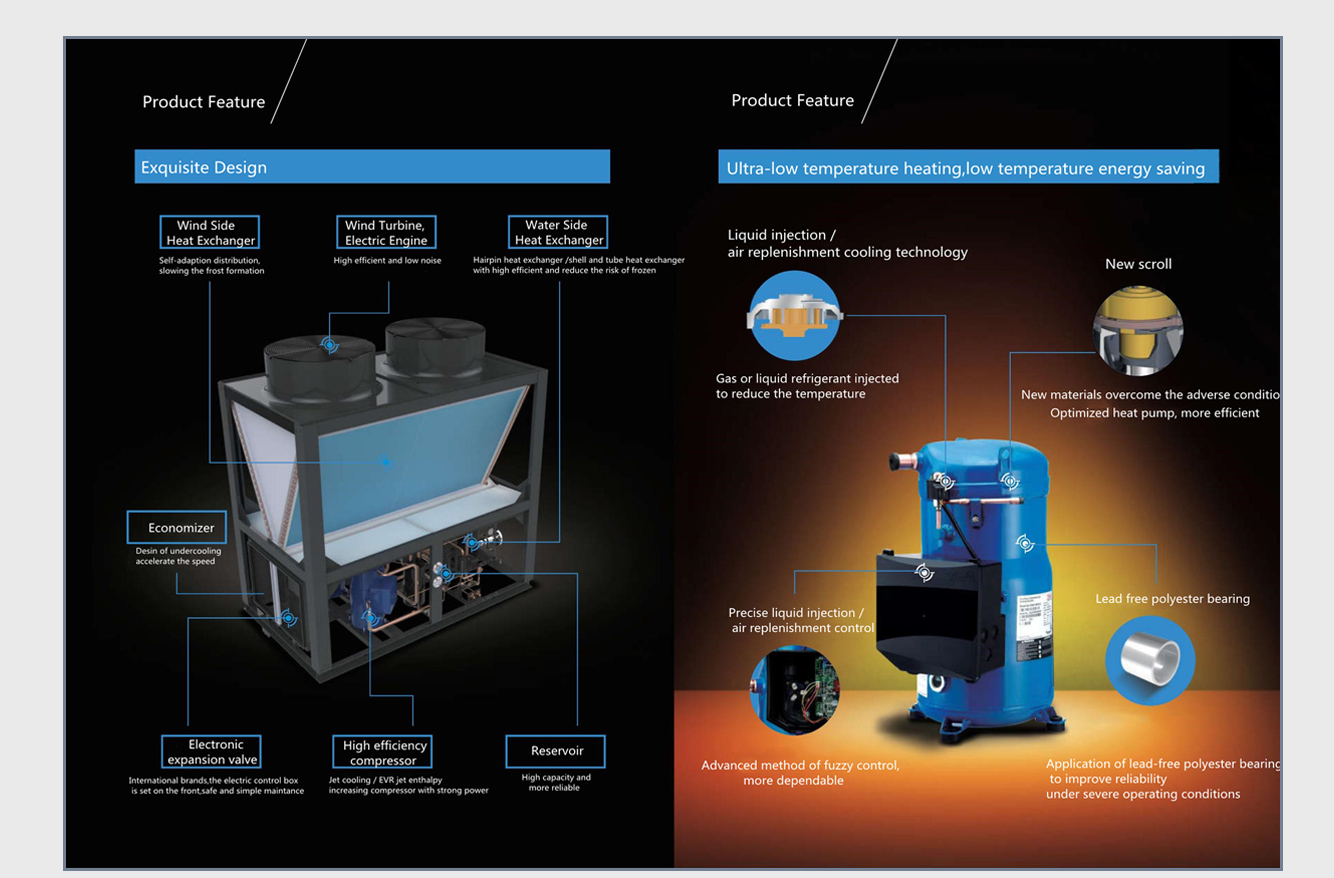

| Throttling Method | Electronic Expansion Valve | ||

| Water Side Heat Exchanger | Shell and Tube Heat Exchanger | ||

| Wind Side Heat Exchanger | High-efficiency Finned Tube Heat Exchanger | ||

| Fan | High Efficiency and Low Noise Axial Flow Fan | ||

| Water System | Chilled Water Flow(m³/h) | 11.2 | 22.4 |

| Hydraulic Pressure Drop(kpa) | 40 | 75 | |

| Maximum Working Pressure(Mpa) | 1.0 | ||

| Water Pipe Connection | DN65(Flange) | DN80(Flange) | |

| Anti-shock Protection Type | Ⅰ | ||

| Waterproof Level | IPX4 | ||

| Dimentions | Length(mm) | 1930 | 2340 |

| Width(mm) | 941 | 1500 | |

| Height(mm) | 2135 | 2350 | |

| Weight(kg) | 590 | 1000 | |

| Rated refrigeration: outdoor dry/wet bulb temperature is 35°C/24°C; outlet water temperature: 7°C | |||

| Rated heating: outdoor dry/wet bulb temperature is 7℃/6℃; outlet water temperature is: 45℃ | |||

| Models, parameters, and performance will be changed due to product improvements. Please refer to the actual product and nameplate for specific parameters; | |||

| Executive Standard:GB/T 18430.1(2)-2007 GB/T 25127.1(2)-2010 | |||

We proudly offer cutting-edge cold storage insulation solutions—polyurethane sheets for cold storage construction—and offer OEM/ODM services. Our sheets are designed to provide superior insulation performance in cold storage, ensuring perishable goods maintain optimal temperatures. We offer a variety of thicknesses, including 50mm, 75mm, 100mm, 150mm, 200mm, and 300mm, providing flexibility to meet diverse insulation needs.

We proudly offer cutting-edge cold storage insulation solutions—polyurethane sheets for cold storage construction—and offer OEM/ODM services. Our sheets are designed to provide superior insulation performance in cold storage, ensuring perishable goods maintain optimal temperatures. We offer a variety of thicknesses, including 50mm, 75mm, 100mm, 150mm, 200mm, and 300mm, providing flexibility to meet diverse insulation needs.

Made from high-quality PU/PIR/PUR/Puf/polyurethane materials, our structural insulated sandwich panels offer superior insulation properties, effectively reducing heat transfer and maintaining a consistent internal temperature. This not only helps preserve the quality and shelf life of stored products, but also improves energy efficiency, ultimately reducing long-term operating costs.

One of the key advantages of our polyurethane sheets is their suitability for OEM/ODM applications. Whether you require custom dimensions, specific thermal conductivity, or unique design features, our sheets can be tailored to your exact specifications. This ensures seamless integration into your cold room architecture and optimizes thermal insulation performance for your specific storage needs.

Not only do our sheets offer superior thermal insulation performance, they are also renowned for their durability and structural integrity. The panels’ robust construction ensures long-term reliability, making them a cost-effective investment for cold storage facilities.

Furthermore, our polyurethane panels for cold storage construction are easy and efficient to install, minimizing downtime during construction or renovations. Furthermore, their low maintenance costs make them a convenient solution for cold storage insulation.

Whether you’re in the food, pharmaceutical, or any other industry requiring refrigeration, our OEM/ODM polyurethane refrigeration panels are the ideal choice for superior insulation performance. Trust our expertise and innovative solutions to improve the efficiency and reliability of your cold storage facilities.

Products categories

-

WhatsApp

-

WhatsApp

WhatsApp

-

E-mail

-

Phone

-

Wechat

WhatsApp