Refrigeration compressor selection principles

1) the compressor cooling capacity should be able to meet the peak load requirements of the cold storage production season, that is, the compressor cooling capacity should be greater than or equal to the mechanical load. Generally in the selection of compressor, according to the hottest season of the year cooling water temperature (or temperature) to determine the condensing temperature, the condensing temperature and evaporating temperature to determine the operating conditions of the compressor. However, the peak load of cold storage production does not necessarily happen to be in the highest temperature season, autumn, winter and spring cooling water temperature (temperature) is relatively low (except for deep well water), the condensing temperature is also reduced, the compressor cooling capacity will be increased. Therefore, the choice of compressor should consider the seasonal correction factor.

2) For small cold storage, such as life service cold storage, the compressor can be selected as a single unit. For larger capacity cold storage and larger cold processing capacity of the freezing room, the number of compressor units should not be less than two. The total refrigeration capacity to meet the production requirements shall prevail, and generally do not consider standby.

3) refrigeration compressor series should not exceed two, such as only two compressors, the same series should be selected to facilitate control, management and spare parts interchange.

4) for different evaporative temperature system equipped with compressors, should also give due consideration to the possibility of mutual backup between units.

5) If the compressor with energy regulating device, can make a large adjustment to the single machine cooling capacity, but only adapted to the operation of load fluctuations in the regulation, should not be used for seasonal load changes in the regulation. Seasonal load or production capacity changes in load regulation, should be separately configured with the refrigeration capacity of the machine, in order to achieve better energy-saving effect.

6) In order to meet the requirements of the production process, the refrigeration cycle is often required to obtain a lower evaporation temperature, in order to improve the delivery coefficient of the compressor and the indicated efficiency, to protect the operational safety of the compressor, a two-stage compression refrigeration cycle should be used. Ammonia refrigeration system pressure ratio Pk/P0 is greater than 8 when the use of two-stage compression; Freon system pressure ratio Pk/P0 is greater than 10, the use of two-stage compression.

7) Refrigeration compressor working conditions, shall not exceed the manufacturer’s given operating conditions or national standards for the use of compressor conditions.

General principles of condenser selection

Condenser is one of the main heat transfer equipment in the refrigeration system. There are many types of condensers, the main consideration in the selection of the water temperature, water quality, water and climatic conditions in the region of the construction of the library, but also with the layout of the room requirements, generally according to the following principles to choose.

1) Vertical water-cooled condensers are suitable for areas with abundant water sources, poor water quality and high water temperature, and are generally arranged outside the machine room.

2) Horizontal water-cooled condensers are suitable for areas with sufficient water, good water quality and low water temperature, and are widely used in small and medium-sized ammonia and Freon systems, and are generally arranged in the equipment room of the machine room.

3) Water-cooled condensers are suitable for areas with low air wet bulb temperature, insufficient water supply or poor water quality, and are generally arranged in a well-ventilated outdoor area.

4) Evaporative condenser is suitable for low relative humidity and water shortage areas, and is usually located in a well-ventilated outdoor area.

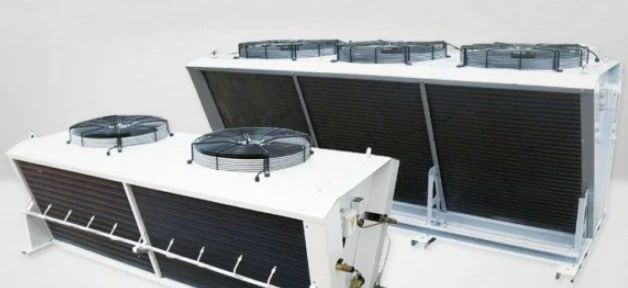

5) Air-cooled condenser is suitable for areas with relatively tight water supply and small Freon refrigeration system. It is generally not used in ammonia refrigeration systems.

In addition, under the condition of meeting the system requirements, factors such as improving heat transfer efficiency, facilitating maintenance and reducing initial investment in equipment should be considered.

Cooling equipment selection of the general principles

Cooling equipment is in the refrigeration system to produce cold effect of low-temperature low-pressure heat transfer equipment, which uses the refrigerant liquid by throttling valve throttling in the lower temperature evaporation, absorbing the heat of the cooled medium (such as brine, air), so that the temperature of the cooled medium is reduced.

The selection of cooling equipment should be determined according to the requirements of food cold processing, refrigeration or other processes, and should generally be selected according to the following principles.

1) the use of the selected cooling equipment and technical conditions should be in line with the current standard requirements of cooling equipment for refrigeration units.

2) cooling room, freezing room and cooling equipment in the cooling room should be used for cooling fan.

3) cooling equipment in the freezer room can be selected from the top exhaust, wall exhaust and chiller. Generally when the food has good packaging, it is appropriate to use the chiller; food without good packaging, can use the top exhaust pipe, wall exhaust pipe.

4) according to different food freezing process requirements to choose the appropriate freezing equipment, such as tunnel freezing, flat freezer front spin freezing device, liquid freezing device and shelf type row pipe freezing device.

5) packaging room cooling equipment in the room temperature higher than -5 ℃ should be used when the chiller, the room temperature below -59 ℃ should be used when the row of pipes.

6) ice storage room using smooth top row pipe.

Post time: May-25-2023